Head Lamp Features and Development Trend

Head lamps usually described as the language with developing trend of times, follow people’s aesthetic tendency, all kinds of high technologie will reflect on the head lamps at first time. Including high beam lights, low beam lights, turn lights, position lights and daytime running lights, now the light source of headlamps transition from halogen, xenon to LED, matrix and Laser source. The product modelling developing in the direction of thin strip and ring shape.

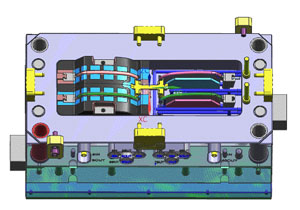

Head Lamp Mold

Eye-catching shapes put forward more and more challenges to head lamp mold, headlamp lens are developing in the direction of double-color mold, mold drop becomes ever larger, the drop of around 600mm-750mm is becoming more common. Thin strip and ring shapes make the mold gating system complex, multi-gate and sequence valve are widely used. Light guide mold and thick wall mold are getting more and more, electroforming core and diamond cutting techniques are used to ensure the optical requirements.

With rich experience in headlamp mold design and manufacturing, our products are widely distributed in most popular models. We are familar with the headlamp products feature requirement, design difficulty and have the corresponding design standards, could flexibility to meet the difficult head lamp mold development.

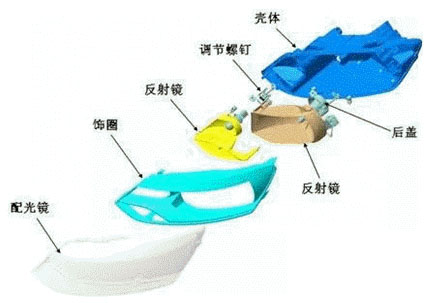

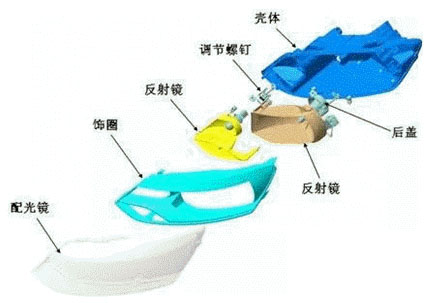

Head Lamp Assembly Exploded View

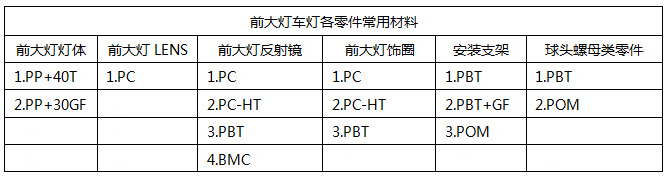

Common Materials:

|

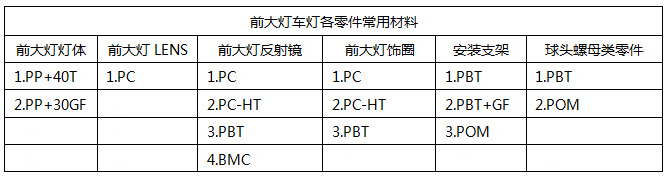

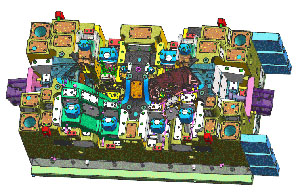

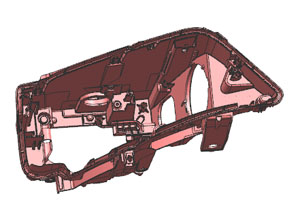

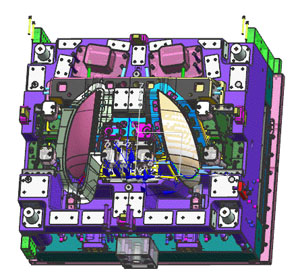

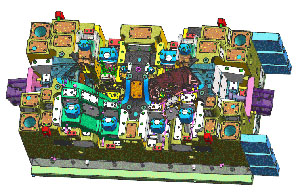

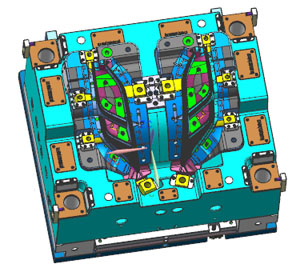

1.1 Head Lamp Housing Mold

Successful Case

Part Case:Q3PA HL(HID)Housing (Audi Q3)

Part Material:PP+30GF

Mold Size:1500mm×900mm×1150mm

Part Size:399mm×399mm×179mm

Mold Weight:10.2 Tons

|

|

|

|

Mold Features of Head Lamp Housing:

Large drop with lots of inserts, the mold need to be easily maintained an dimention adjusting. Complex mold structure and multiple parting, zero core puller. Smooth part release without release agent.

|

|

|

|

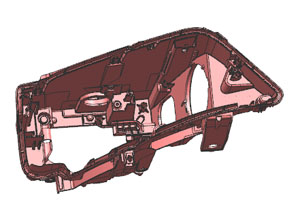

Product Features of Head Lamp Housing:

Require gas tightness, strict part dimension requirement, focus on dimming slot size and boss position, material PP+40T easy to lead shrinkage and bad creep resistance. Material PP+30GF easy to lead the part deformation. The left part housing and the right housing are not very symmetric(lettering, rear cover structure, LTM structure, non-mirrored connecter structure). Control the parting segment difference and ejector pin trace below 0.2mm. Keep the part surface smooth, free of defects such as bubbles, flow mark and sink mark, activating treatment is necessary before coating.

|

|

|

|

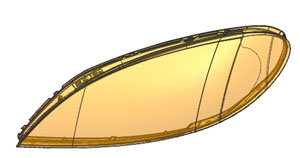

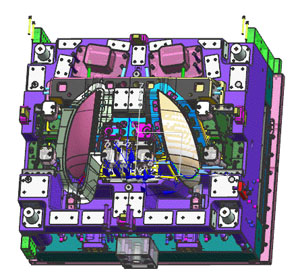

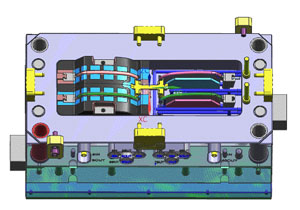

1.2 Head Lamp Lens Mold

Successful Case

Part Case:J200 HL LENS

Thick Wall:2.6mm

Part Material:PC

Mold Size:1300mm×1050mm×1170mm

Part Size:442mm×419mm×191mm

Mold Weight:11.5 Tons

|

|

|

|

Mold Features of Head Lamp Lens:

Unicolor injection mold usually with big angle core-pulling mechanism. There is outer slide core-pulling around the product, complex coolling system, high mold machining precision requirement, core-pulling split line, uniform segment difference. Double injection mold usually use inversion forming.

|

|

|

|

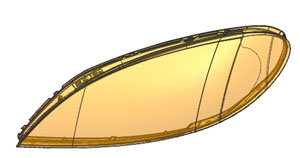

Product Features of Head Lamp Lens:

With transparent material PC, the product have the requirement on appearance and light matching, light matching pattern in the middle of the product. There are two kinds of head lamp lens: unicolor lens and bi-color lens. Unicolor part we could see the core-pulling split line, and invsible line on the bi-color part. Lace pattern usually exists on the side wall of unicolor part.

|

|

|

|

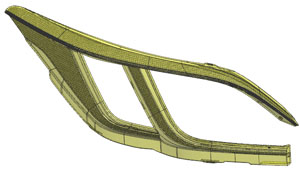

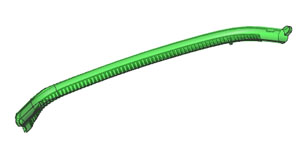

1. 3 Head Lamp Transparent and Al-Plating Bezel Mold

Successful Case

Part Case:645A HL Inner Lens E

Part Material:PC 1225Z

Mold Size:850mm×790mm×870mm

Part Size:167mm×330mm×328mm

Mold weight:5.6 Tons

|

|

|

|

Mold Features of Head Lamp Transparent Bezel:

Large drop of product, complex cooling system, The information such as core-pulling split line, ejection mark and gating position should be approved by customers. Mold patterns need to be done by one time processing on CNC. To prevent the groove of plating cover from flow mark.

|

|

|

|

Product Features of Head Lamp Transparent Bezel:

Product material usually PC, transparent or milk white or with local texture area. With pattern or al-plating in local area. There is usually groove of plating cover in the plating area and un-plating area.

|

|

|

|

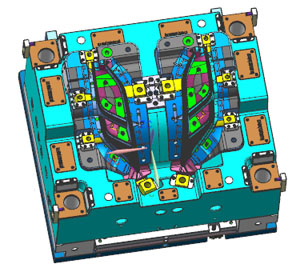

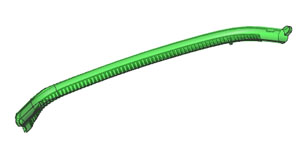

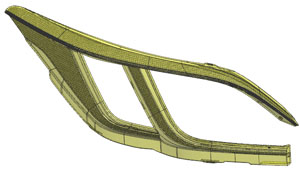

1. 4 Head Lamp Light guide Mold

Successful Case

Part Case:GL8 Light Guide

Part Material:PC 1225Z

Mold Size:850mm×790mm×870mm

Mold Weight:5.6 Tons

|

|

|

|

Mold Features of Head Lamp Light Guide:

Light guide mold with complex parting surface, large drop of products. The cooling system design has great influence on the product molding cycle and derformation control. Reflector pattern is done by electroforming or high speed machining as require. Reasonable gate location, or will effect the optical property. The gate location and ejection line shoud be approved by customers.

|

|

|

|

Product Features of Head Lamp Light Guide:

Usually PC or PMMA material, products with thick wall, have round shape, square or other shapes, with complex spatial shapes. The products often have serrated pattern and with optical requirement. Mounting angle around the ligt guide.

|

|

|

|

|