Fog Lamp Features and Development Trend

Automotive fog lamps open under the condition of low visibility, could let others see your vehicle position with strong light penetrating power. At present, the main light source including gas bulb source, LED source and future laser source. To keep the strong light penetrating power, the light power and the temperature classification of parts are very high, so the material of fog lamp reflector bowls usually PEI, and LED light source normally use aluminum alloy die-casting to enhance heat dissipation.

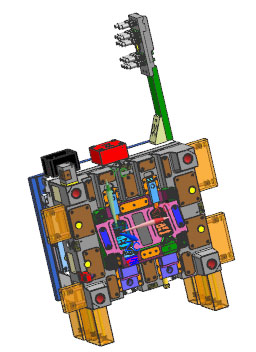

Fog Lamp Mold

It requires high heat resistance for fog lamp parts, so the reflector bowls normally use the material PEI, the mold temperature is very high, cavity material selection and machining parameter of reflection pattern become important. Fog lamp housing usually us choose high heat resistance material PBT+30GF, the gate location is very important.

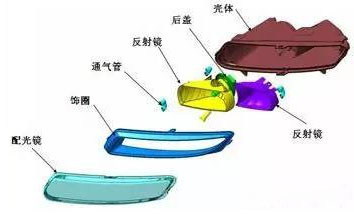

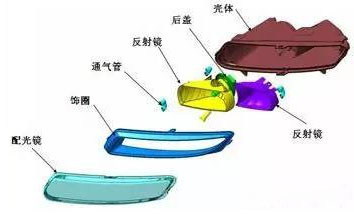

Fog Lamp Assembly Exploded View

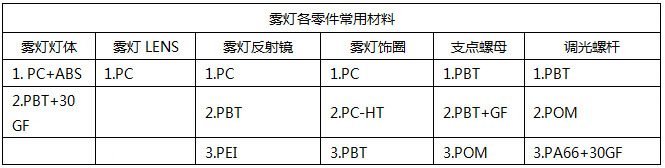

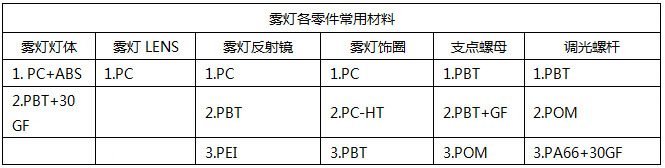

Common Materials:

|

3.1 Mold of Fog Lamp Lens

Successful Case

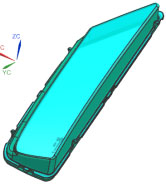

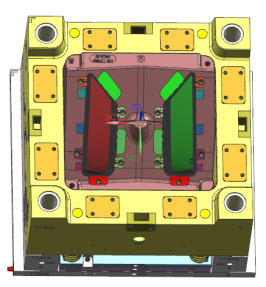

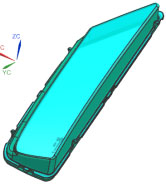

Part Case:Front Fog Lamp Lens

Part Material:PC

Mold Size:750mmX720mmx750mm

Part Size:103mmX253mmX212mm

Mold Weight:2.3 Tons

|

|

|

|

Mold Features of Fog Lamp Lens:

Fog lamp lens normally need to do mirrored polishing, large drop of products, and side gate injection. Wall thickness optimization to avoid air trapping when design. The side Lace pattern done by five-axis machining. The product date locations and ejection lines all need to get approved from customers.

|

|

|

|

Product Features of Fog Lamp Lens:

Normally PC material, lace patterns on the product side wall, hard mask plating is required on the products.

|

|

|

|

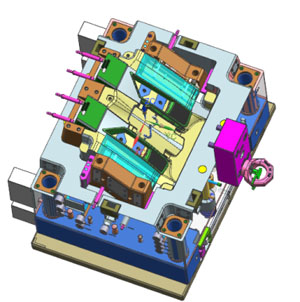

3. 2 Mold of Fog Lamp Bezel

Successful Case

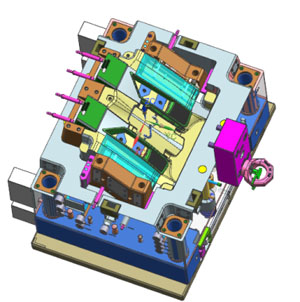

Part Case:Front Fog Lamp Bezel

Part Material:PC-HT

Mold Size:850mm×780mm×725mm

Part Size:95mm×230mm×200mm

Mold Weight:2.52 Tons

|

|

|

|

Mold Features of Fog Lamp Bezel:

Front fog lamp bezel mold with complex parting surface, large drop of products, normally hot runner with spreader plate. Slider core-pulling around the mold, cooling system with heat resisting seal ring. High machining precision, no flash allowed or it will effect the aluminum plating and product appearance.

|

|

|

|

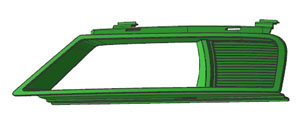

Product Features of Fog Lamp Bezel:

Normally PC-HT or PBT material, the products have the requirement of high temperature resistance and aluminum plating. Only one structural weld line on the product allowed, keep the surface clean, no flow mark and fogging.

|

|

|

|

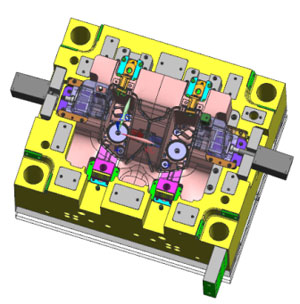

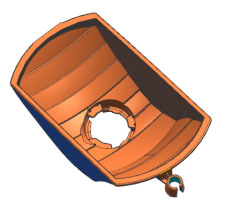

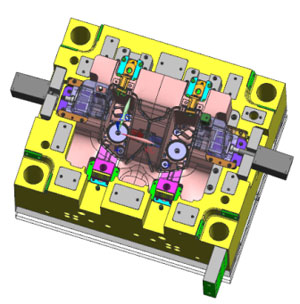

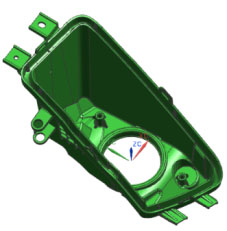

3. 3 Mold of Fog Lamp Housing

Successful Case

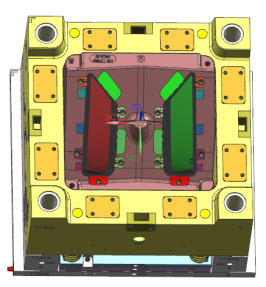

Part Case:MODEL Z Front Fog Lamp Housing

Part Material:PBT+30%GF

Mold Size:800mm×650mm×864mm

Part Size:132mm×239mm×223mm

Mold Weight:3.2 Tons

|

|

|

|

Mold Features of Fog Lamp Housing:

Fog lamp housing mold with complex parting surface, large drop of products, normally hot runner with spreader plate. As glass fiber orientation has bad influence on gas tightness, corresponding strategy is need before mold making. The mold structure is complex, core-pulling mechanism of inclined dimming axis hole is very important when design.

|

|

|

|

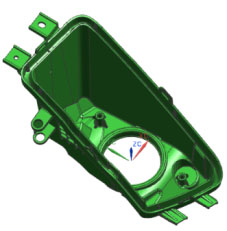

Product Features of Fog Lamp Housing:

Normally PBT+30GF material, products with gas tightness and temperature resistance, and the dimming axis hole is usually compound angled inclined hole.

|

|

|

|

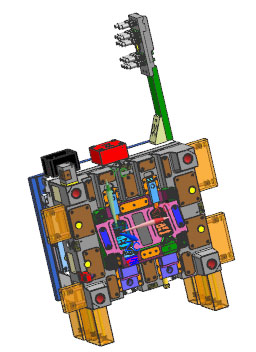

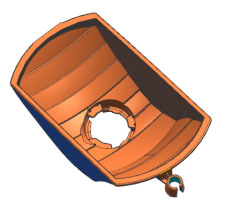

3. 4 Mold of Fog Lamp Reflector

Successful Case

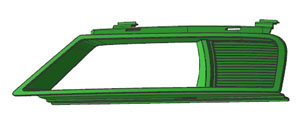

Part Case:SKODA YETI Front Fog Lamp Reflector

Part Material:PEI

Mold Size:730mm×740mm×660mm

Part Size:63mm×121mm×83mm

Mold Weight:1.27 Tons

|

|

|

|

Mold Features of Fog Lamp Reflector:

Fog lamp reflector mold with complex parting surface, normally hot runner with spreader plate. Gate from the middle of the products. The reflection pattern is machined by 30,000 rpm high speed CNC with one time process. Hand polishing is prohibited. Mold cooling system design is the key. Sealing ring should have high temperature resistance, thermal insulation around the mold.

|

|

|

|

Product Features of Fog Lamp Reflector:

Normally PEI or PBT material, PEI with high inter temperature, good liquidity, small excessive value. Products with reflection bowls, lace patterns on the bowl side wall, also need aluminum plating.

|

|

|

|

|