|

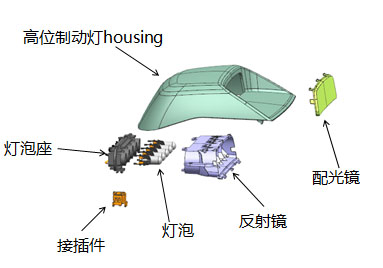

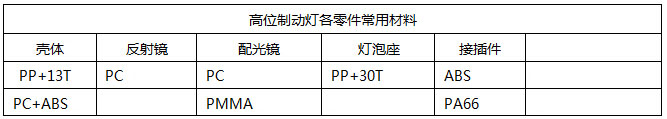

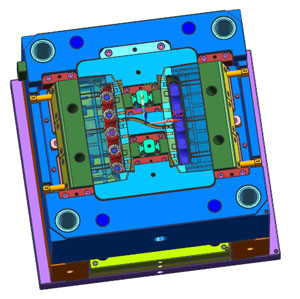

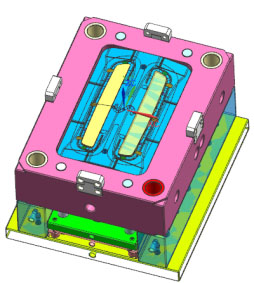

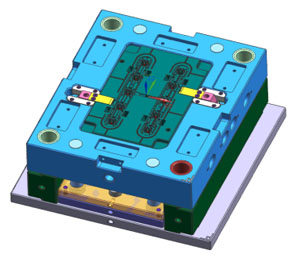

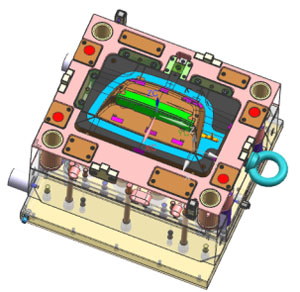

6.1 Mold of High Brake Lamp Housing

Successful Case

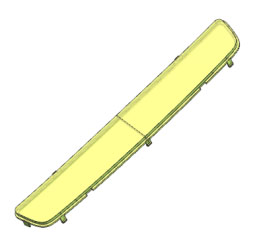

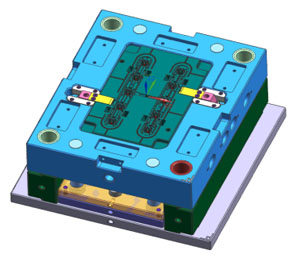

Part Case:SGM-15 High Brake Lamp Rear Housing

Part Material:PP+13T

Mold Size:600mm×550mm×610mm

Part Size:178mm×297mm×70mm

Mold Weight:1.1Tons

|

|

|

|

Mold Features of High Brake Lamp Housing

Mold parting surface is complex, with one cavity, hot runner system with spreader plate, gating from the part side. Reliable cooling system design to avoid the products warpage and shrinkage. Use lifters to reach core-pulling.

|

|

|

|

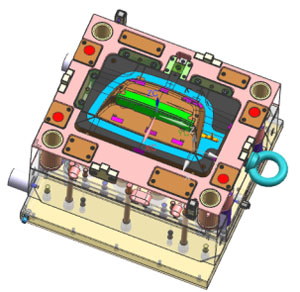

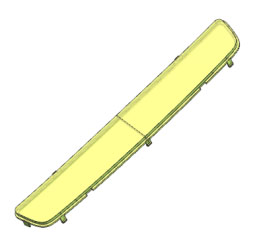

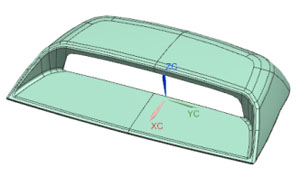

Product Features of High Brake Lamp Housing

Material usually PP+13T or PC+ABS, texture is required and mounting angle on the back of the products. Thick wall design of the products is to avoid stress mark, usually between 3.0mm to 3.5mm. Uniform color on the part surface, without flash and stress marks.

|

|

|

|

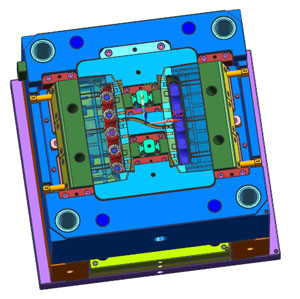

6.2 Mold of High Brake Lamp Reflector

Successful Case

Part Case:SGM-15 Reflector

Part Material:PC

Mold Size:430mm×600mm×380mm

Part Size:35mm×236mm×57mm

Mold Weight:820KG

|

|

|

|

Mold Features of High Brake Lamp Reflector:

Reflector mold with two cavities. Reflection patterns required high precision machining by high speed CNC with one time processing. Hand polishing is forbidden. Mold usually with slider core-pulling on moving side.

|

|

|

|

Product Features of High Brake Lamp Reflector:

Material is usually PC, there is reflection bowl on the product, lace pattern on the bowl side wall, required to do aluminum plating. Products have the requirements of light distribution.

|

|

|

|

6.3 Mold of High Brake Lamp Lens

Successful Case

Part Case:SGM-15 Lens

Part Material:PC

Mold Size:400mm×350mm×335mm

Part Size:15mm×220mm×35mm

Mold Wight:310KG

|

|

|

|

Mold Features of High Brake Lamp Lens:

The moving side and the fixed side of lens mold have the requirements of mirror polishing, the snap joint of the product need to do inserts on the mold, for ease of dimension adjusting.

|

|

|

|

Product Features of High Brake Lamp Lens:

Material is usually PC, the color of product is often red and transparent. The snap joints are located around the products.

|

|

|

|

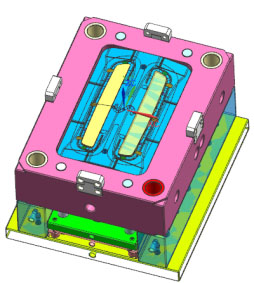

6.4 Mold of High Brake Lamp Socket

Successful Case

Part Case:SGM-15High Brake Lamp Socket

Part Material:PP+30T

Mold Size:400mm×400mm×325mm

Part Size:25mm×210mm×35mm

Mold Weight:305KG

|

|

|

|

Mold Features of High Brake Lamp Socket:

Lamp socket molds often with two cavities, the bulb mounting positions all have corresponding inserts on the mold, and the inserts are marked with lettering in order to avoid the fixed assembly when do mold maintenance. It belongs to the precision molds.

|

|

|

|

Product Features of High Brake Lamp Socket:

Material is usually PP+30T, the dimensions of bulb grooves with high requirements, all dimensions of bulb mounting positions to be the same.

|

|

|