Tail Lamp Features and Development Trend

Automotive tail lamp assembly including brake lamp, turn lamp and driving lamp. The light source of tail lamp developed from the bulb to LED, next step is OLED and laser source.

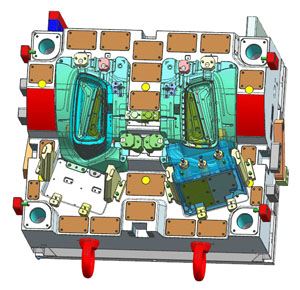

Tail Lamp Mold

Tail lamp lens mold is developing in the direction of three-color and four-color mold. Tail lamp bezel mold developing from unicolor mold to double-color mold. With the combine and simplify of tail lamp components, there is area to have both light matching pattern and texture on tail lamp housing mold, it does make the mold developing more difficult.

Tail lamp part material ABS or PC+ABS, usually need aluminum plating. Most tail lamp housing parts have complex structures, multiple reflector bowls on the front side, need aluminum plating; Mounting points and sealing ribs on the back side, leads more inserts of tail lamp housing mold. Slider, inner core-pulling and lifter are widely used to ensure smooth mold release. Housing lamp socket should be inserts as soon as possible, bulb socket is forming by shut-off, the shapes of left and right part are translational, it is easy to do machining, adjusting and modify if done to be inserts. Ejectors of tail lamp housing mold are mostly round ejectors, as well as pipe ejector, blade ejector and block ejector. Cooling system should be considered when design inserts as patterned inserts and big inserts need water route, some inserts are required to be cooling with BeCu material if necessary.

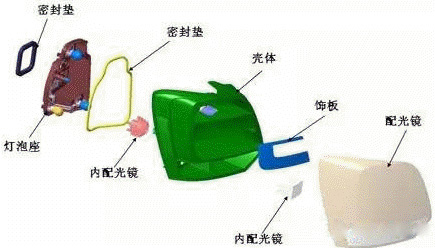

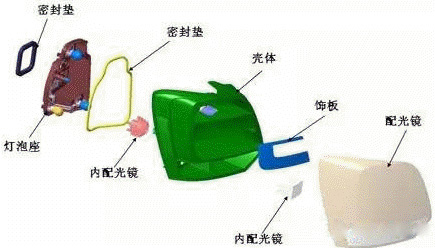

Tail Lamp Assembly Exploded View

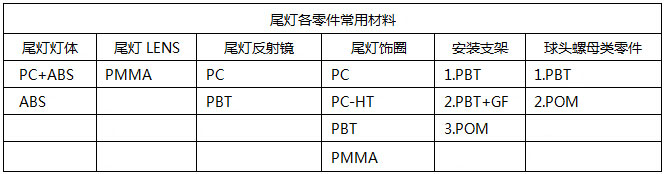

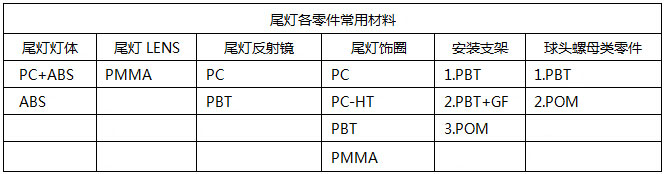

Common Materials:

|

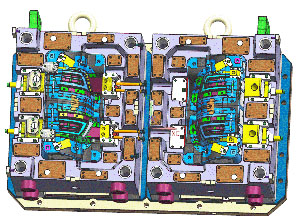

2.1 Mold of Tail Lamp Bi-color Bezel

Successful Case

Part Case:NEW LAVIDA Tail Lamp Bi-color Bezel

Part Material:PC

Mold Size:1460mm×900mm×870mm

Part Size:179mm×162mm×224mm

Mold Weight:6.3 Tons

|

|

|

|

Mold Features of Tail Lamp Bi-color Bezel:

Bi-color bezel mold with complex parting surface, large drop of products, sealing angle is usually very thin, easy replace and maintenance should be considered when inserts design. Complex cooling system. High machining precision, or burrs will happen. Mold should be made to meet the requirement of automatic production.

|

|

|

|

Product Features of Tail Lamp Bi-color Bezel:

Usually PC or PMMA material, the products with local aluminum plating area and local texture are, there is usually groove of plating cover in the plating area and un-plating area, milk white one with light matching requirement. The products color are uniform, clean surface, without crack and flow mark in the connection area.

|

|

|

|

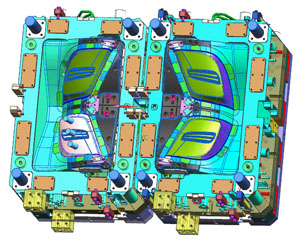

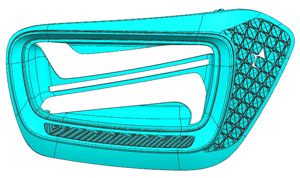

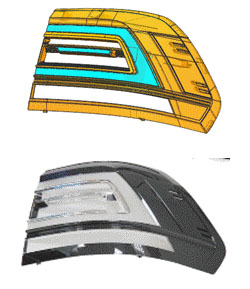

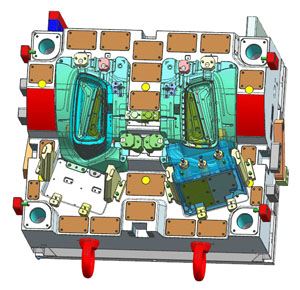

2.2 Mold of Tail Lamp Bi-color Lens

Successful Case

Part Case:T300 NB Tail Lamp Lens

Part Material:PMMA

Mold Size:1770mm×1164mm×961mm

Part Size:356mm×273mm×332mm

Mold Weight:9.95 Tons

|

|

|

|

Mold Features of Tail Lamp Bi-color Lens:

Bi-color lens mold with complex parting surface, large drop of products, valve needle gating of the first two shots, angled valve needle system if required, mold cost is high. Mold usually with inclined core-pulling mechanism, complex mold structure and cooling circuit. High machining precision, or burrs will happen. Mold should be made to meet the requirement of automatic production.

|

|

|

|

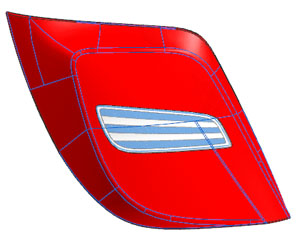

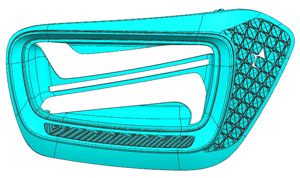

Product Features of Tail Lamp Bi-color Lens:

Material is usually PMMA, welding ribs around the products, with decorative pattern or light matching pattern. Kinds of products including bi-color lens, three-color lens and covered lens according to the structure design. Products with high brittleness. The sink marks from welding ribs of bi-color lens are easy to show.

|

|

|

|

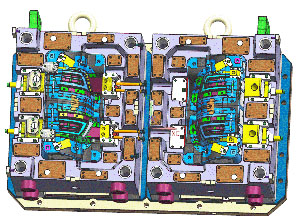

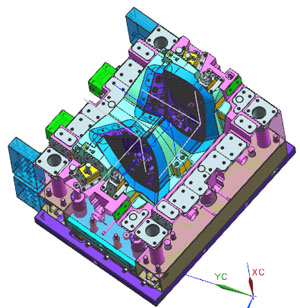

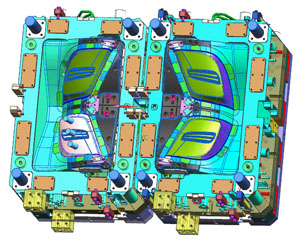

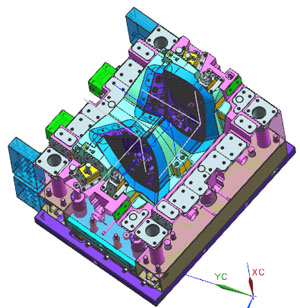

2. 3 Mold of Tail Lamp Housing

Successful Case

Part Case: Tail Lamp A Housing

Part material:PC+ABS

Mold Size:1000mm×983mm×1065mm

Part Size:211mm×274mm×340mm

Mold Weight:5.2 Tons

|

|

|

|

Mold Features of Tail Lamp Housing:

Tail lamp housing mold has complex parting surface, large drop of products, hot runner with spreader plate. The mold patterns are made by CNC one time processing, hand polishing is prohibited. Usually with inclined core-pulling mechanism in cavity or in core.

|

|

|

|

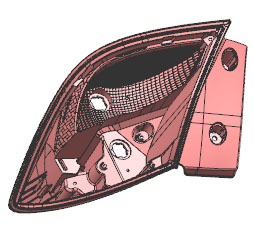

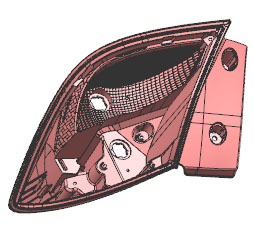

Product Features of Tail Lamp Housing:

Material is usually PC+ABS or ASA, reflector bowls on the products, lace pattern on the bowl side wall, need local aluminum plating and gas tightness requirement, welding ribs around the products, side panel with texture.

|

|

|

|

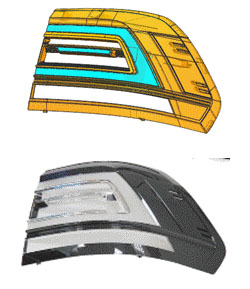

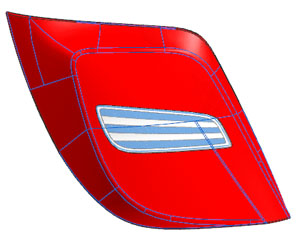

2. 4 Mold of Tail Lamp Bezel

Successful Case

Part Case:B751 Tail Lamp Assembly Bezel

Part Material:PC

Mold Size:1150mm×995mm×1019mm

Part Size:209mm×335mm×285mm

Mold Weight:7.1Tons

|

|

|

|

Mold Features of Tail Lamp Bezel:

Tail lamp bezel mold has complex parting surface, large drop of products, hot runner with spreader plate. The mold patterns are made by CNC one time processing. Usually with cavity core-pulling, outer slide core-pulling and lifter core pulling. High machining precision, or scratch will happen when mold release.

|

|

|

|

Product Features of Tail Lamp Bezel:

Material usually PC+ABS or PC,LED reflector bowls on the products, lace pattern on the bowl side wall, local aluminum plating and some have local texture requirement, there is groove of plating cover in the plating area and un-plating area. High product appearance requirement, no weld line and flow mark.

|

|

|

|

|